Flywoo X30 Waterproof Superhydrophobic Invisible Spray creates an effective waterproof coating for electronic modules, meeting nearly all your needs. Positioned to provide daily waterproofing for drones most easily.

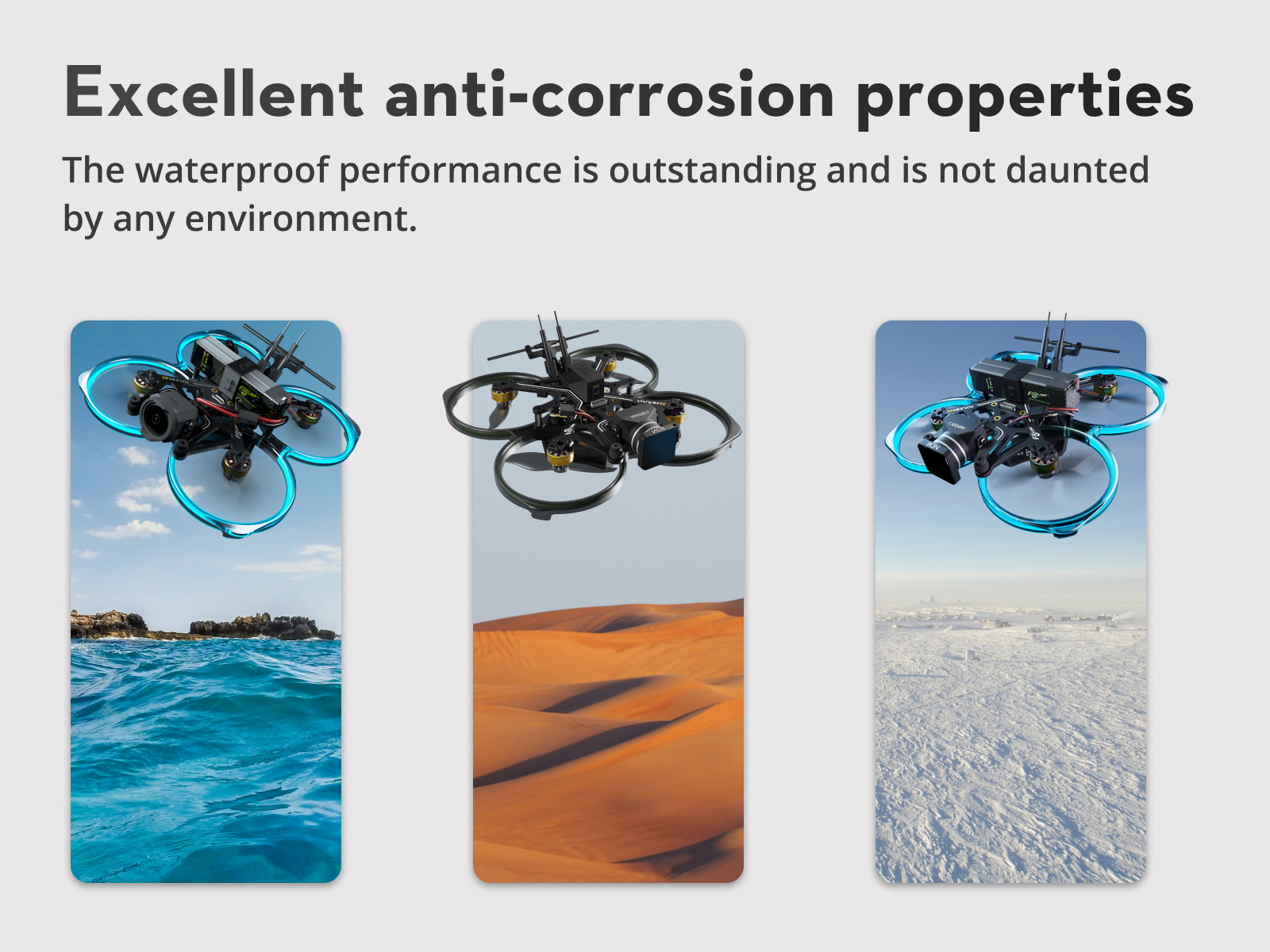

Superhydrophobic materials are ideal materials used in electronic products for waterproofing. The superhydrophobic material resembles the surface of a lotus leaf. Due to its unique repellency to water or water vapor, superhydrophobic materials have inherent and natural functions of preventing water, moisture, salt spray, mold, dust, corrosion, short circuit, etc.

With just a simple spray, a highly effective waterproof coating is formed within 2-3 minutes, allowing your electronic products to withstand water splashes and remain usable even on rainy days.

Operating Instructions:

Application Scope:

●Covering all circuit boards (Flight Controller, Electronic Speed Controller, Video Transmitter, O3, etc.)

●Glass materials such as lenses (Can effectively prevent water droplets from adhering, but it will reduce the permeability by 30%. If dissatisfied after application, it can be wiped clean)

●Plugs on all circuit boards

●Plugs on the battery

Product Name: Flywoo X30 Waterproof Superhydrophobic Invisible Spray

Capacity: 56.7g (For example: Flywoo GOKU F722 PRO Mini V2 20X20 Flight Controller double-sided spray 3 times, need to use 2.5g)

Material: Superhydrophobic material

Purpose: Used for waterproofing, short-circuit prevention, corrosion resistance, salt spray protection, mold resistance, dust prevention, and heat dissipation in electronic products.

Long-lasting Protection of Flywoo X30 Waterproof Spray

When the coating remains undamaged (after spraying and in a static state), it has been tested by Huawei and Midea and the protection effect lasts for up to 8 years. When sprayed on drones, as impacts and other accidents may occur during flight and damage the coating, we recommend re-spraying before each flight

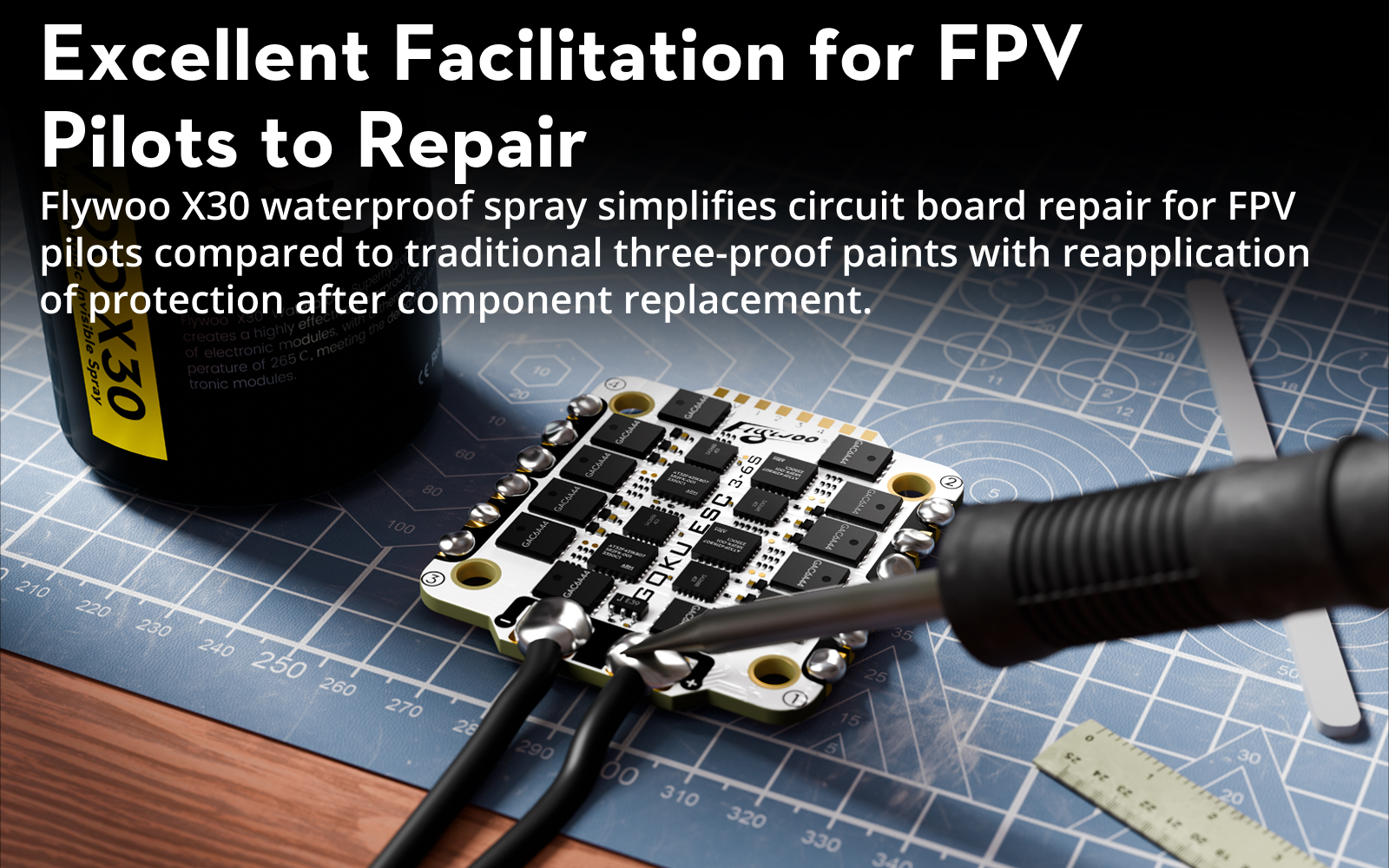

Excellent Facilitation for FPV Pilots to Repair

Flywoo X30 waterproof spray simplifies circuit board repair for FPV pilots compared to traditional three-proof paints with reapplication of protection after component replacement.

Excellent Safety

The Flywoo X30 waterproof spray is an environmentally friendly product that does not contain harmful substances. However, traditional three-proof paints may release volatile organic compounds (VOCs), which have certain impacts on the environment and human health.

Comparison to Traditional Conformal Coatings

The protective performance of the three-proof paint relies largely on the compactness of the coating. This is also the focus of the research and development for three-proof paint manufacturers. Moreover, the super-hydrophobic coating inherently possesses natural characteristics such as waterproofing, anti-short circuit, anti-corrosion, anti-salt spray, anti-mold, and anti-dust. Consequently, superhydrophobic materials are ideal alternatives to conformal coatings!

| The needs of the electronics industry |

Superhydrophobic Coating |

Conformal Coating |

|

waterproof |

The biggest feature of superhydrophobic is waterproof |

Depends on coating density |

|

Short circuit prevention |

Excellent anti-short circuit characteristics due to repellency of water / moisture / corrosive liquids |

Depends on coating density |

|

Corrosion protection |

Natural repellency of water or corrosive liquids for excellent corrosion protection properties |

Depends on coating density |

|

saltfog-proof |

Excellent anti-salt spray properties due to natural repellency of salt spray |

Depends on coating density |

|

fungi-proof |

Hydrophobic and dry surface will not harbor bacteria |

Adding anti-mold additives, which will affect the compactness of the coating |

|

dustproof |

Self-cleaning effect similar to lotus leaf to prevent dust |

No dustproof effect |

|

radiating |

Inorganic-organic composite coating to improve heat dissipation |

Poor heat dissipation of polymer materials |

Excellent Performance Parameters

The super-hydrophobic coating has been tested on the PCB circuit board of Huawei's 5G base station. It has undergone three rounds of tests before and after, and its performance is significantly superior to that of 3M's conformal paint.

Huawei Case: Super Hydrophobic VS 3M Conformal Coating

| Comparison Items | Our Superhydrophobic Coating | 3M Conformal Paint |

|---|---|---|

| Thickness | ~20µm | ~40µm |

| Contact Angle | 160° | 80° |

| Wettability (water) | Completely non-wetting | Semi-immersion |

| Wet and Dry Cycle | No change in contact angle after 1000 times | After 100 times, the contact angle becomes 30° |

| Salt Spray Performance | 1000 h | 500h |

| Adhesion Level | 0 level | 0 |

| Anti-short Circuit Time (Accelerated Test in a Salt Spray Chamber) | 1500h | 1000h |

Based on the comparison above, this superhydrophobic coating clearly outperforms 3M's conformal coating in various performance metrics, including:

1. Thinner coating thickness - The superhydrophobic coating only requires 20-50 μm, compared to 40-120 μm for the traditional conformal coating.

2. Higher hydrophobicity - The superhydrophobic coating has a contact angle of 160°, while the 3M coating is only 80°, indicating much stronger water repellency.

3. Superior durability - After 1000 wet-dry cycles, the superhydrophobic coating maintained its contact angle, whereas the 3M coating dropped to 30° after just 100 cycles.

4. Enhanced anti-corrosion and anti-short circuit performance - The superhydrophobic coating achieved 1000 hours of salt spray resistance and 1500 hours of anti-short circuit time, outperforming the 3M coating's 500 hours and 1000 hours respectively.

These significant advantages make the superhydrophobic coating an ideal protective solution for the electronics industry. Its combination of thin profile, extreme water repellency, and outstanding durability and protective capabilities make it a superior alternative to traditional conformal coatings.

Excellent heat dissipation

The thickness of conventional conformal paint is 40 - 120µm, but our super-hydrophobic coating only needs 20 - 50µm.

| Resin Type | Acrylic Resin | Epoxy Resin | Silicone Resin | Polyurethane Resin | p-xylene | Our Superhydrophobic Materials |

|---|---|---|---|---|---|---|

| Thermal Conductivity (W/mk) | 0.2 - 0.8 | 0.2 - 1 | 0.8 - 1.2 | 0.35 - 1.1 | 0.2 - 0.5 | 3.3 |

| Thermal Resistance (10⁻⁴m²K/W) | 1 - 4 | 0.8 - 4 | 0.6 - 1 | 0.7 - 2.2 | 1.6 - 4 | 0.1 |

The data comparison indicates that our superhydrophobic material has an impressive thermal conductivity of 3.3 W/mK, which is significantly higher than common resin-based coatings. Additionally, its thermal resistance is only 0.1 x 10⁻⁴m²K/W, far superior to other materials.

This means that, compared to traditional coatings, our superhydrophobic coating can more effectively aid in heat dissipation for electronic devices, thereby enhancing overall thermal performance. This is particularly crucial for high-power electronic products.

In summary, with its excellent thermal conduction properties, our superhydrophobic coating can provide superior heat dissipation for electronic products, making it an ideal protective solution.